Leaving equipment unplugged to check utilization?

Since the start of IoT, accurate and reliable data for CapEx equipment utilization has been a challenge that often times gets abandoned. Even in the age of technology we live in – a cost effective and scalable solution seems to elude the market. PC based automation equipment and instruments have helped, but for all the Category or Class 1 assets types, finding a suitable approach to gain insights can sometimes mean exorbitant additional costs added to the asset or laborious man hours to deploy or collect data detracting from productivity.

While there are some work-a-rounds, do they really address the problem? Let’s take a look at a couple examples and see if there isn’t a better way;

- Some RTLS applications can provide accurate location of equipment and people. The thought is that if you can determine an assets’ location or the staff associated to it – you can deduce equipment usage from the location data. While this approach seems logical it allows for such a broad range of variables that the reliability factor is easily discounted. This becomes even more apparent in lab environments where equipment is not typically mobile or do not move frequently and without very expensive precise location solutions, determining who is standing at a machine will be impossible. Combine all these factors with equipment running without an operator in front of them and you end up with a very expensive and completely unreliable option.

- Some suppliers take the approach of integrating sensors to the equipment to provide information that can extract data and analyze it to create usage databases. While this is a better option to get reliable data it too has some significant limiting factors to be cost effective. Due to the wide range of makes/models this approach can prevent it from being scalable or cost effective. The added cost of external sensors, integration efforts combined with the challenge of deciphering the data to make it actionable makes this option equally challenging.

- One of the most interesting options presented by a new customer was the good ole – unplug it method. Once a specific piece of equipment was suspected of being under-utilized or not being used at all, they would simply unplug it from the outlet and wait for a period of time. There was only the physical labor involved of going around to each plug to assess if anyone had plugged the asset in, but human nature could also have been at work. What if the person plugged it in to use it and then creatively thought it was suppose to be unplugged afterwards? How many times did equipment get a service call because a technician thought the equipment had failed? So while this probably was the least expensive example compared to the ones above, it too was not reliable enough to make big decisions from.

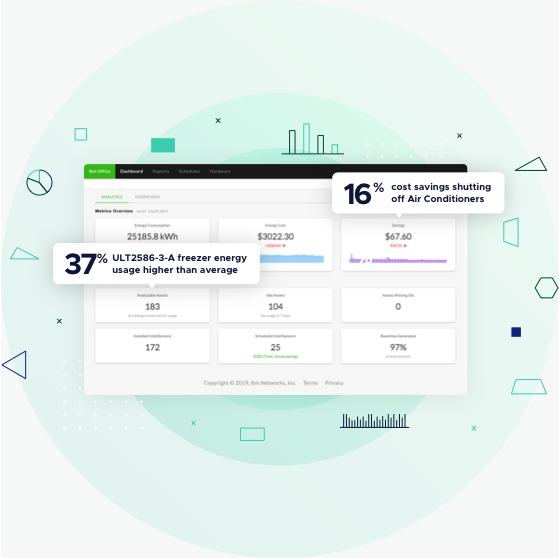

What if the best option is available today in the form of a low cost IoT device that addresses the challenges head on by simply plugging your equipment in? Ibis Networks is the only company that tells enterprises how electrical devices are being used based on the consumption of electricity, unlocking the hidden value of under-utilized assets. Our secure, scalable, reliable, and easy to manage cloud-based platform provides real-time data for decision-makers on actual equipment usage, location tracking, and device health and safety, resulting in CapEX and OpEX savings. Contact us to learn how your company can overcome these challenges and start seeing immediate cost savings.